One area that’s often overlooked during system design is the end connection type used with rupture disk assemblies. For engineers working on propulsion lines, vacuum chambers, or cryogenic storage, selecting the right fitting can make the difference between a mission-ready system and one that fails under pressure.

One area that’s often overlooked during system design is the end connection type used with rupture disk assemblies. For engineers working on propulsion lines, vacuum chambers, or cryogenic storage, selecting the right fitting can make the difference between a mission-ready system and one that fails under pressure.

Why Fittings and Connections Matter

Rupture disks are installed in environments with extreme thermal and mechanical loads. The end connection, if not correctly specified, can introduce leak paths, sealing issues, or mechanical stress that jeopardize system integrity.

A poorly selected or mismatched fitting can compromise the performance of a rupture disk even if the disk itself is correctly rated. Material mismatches, thread types, and incompatible sealing faces are common root causes of performance loss.

Common End Connection Types

Engineers have several options when it comes to end connections. Selection depends on pressure class, cleanliness requirements, reusability, and installation constraints.

1. Threaded Connections

Threaded fittings are often seen in test equipment and non-flight hardware. They provide quick assembly but come with sealing and vibration challenges.

- Straight Threaded (e.g., UN/UNF, BSPP): Requires O-rings or gaskets.

- Tapered Pipe Thread (e.g., NPT, BSPT): Seals via metal-to-metal contact, often with PTFE sealants.

Best for: Ground-based purge systems, test stands, or secondary service lines.

Engineering Insight:

Avoid using tapered threads in vibration-sensitive applications. Over-tightening or galling can distort sealing faces and result in leak paths.

2. Compression Fittings

Ideal for small-diameter tubing, these fittings offer ease of assembly and reusability without the need for welding.

- Standard Compression: Utilizes a ferrule to achieve a mechanical seal.

- Flare (JIC/SAE 37°): Creates a reliable metal-to-metal seal, often seen in ground support and sensor packages.

Best for: Instrumentation lines, thermal control loops, and systems where periodic disassembly is required.

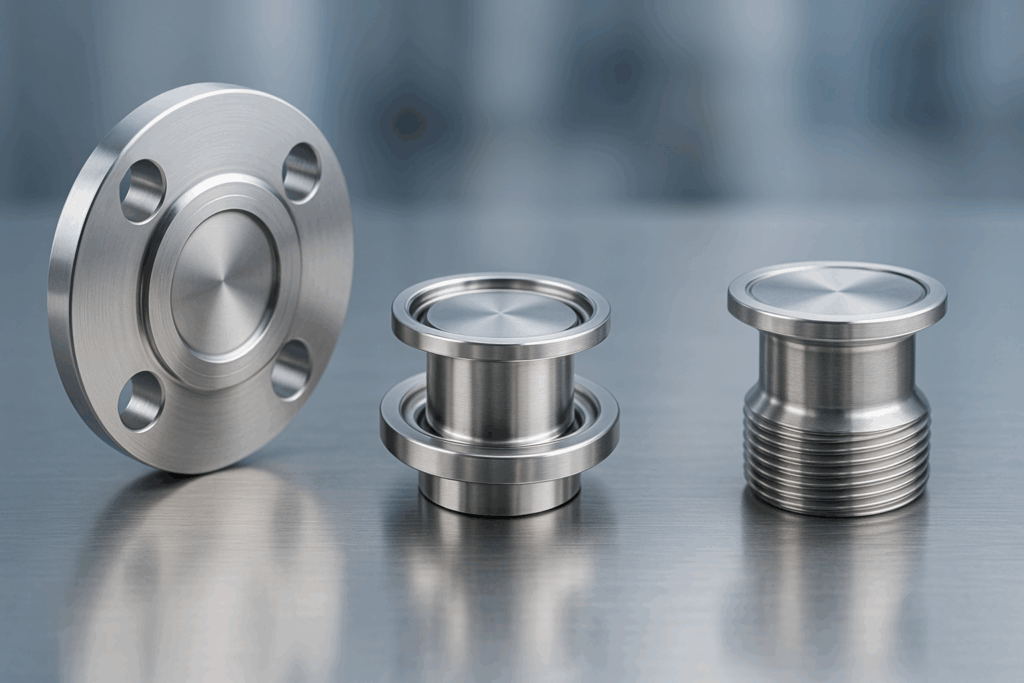

3. Flanged Connections

Flanges provide robust, repeatable sealing for high-pressure or high-vacuum service. Subtypes include:

- ANSI / DIN Flanges: Common in test facilities and ground infrastructure.

- Sanitary Ferrules (Tri-Clamp): Occasionally used in clean or sanitary systems.

- ISO-KF / CF Flanges: Used in ultra-high vacuum and cryogenic storage.

Best for: High-integrity systems where space allows such as vacuum tanks, cryogenic test beds, and launch vehicle infrastructure.

Engineering Insight:

High-vacuum flanges must maintain seal integrity through multiple thermal cycles. Surface finish, flatness, and gasket selection are critical for CF and KF-type flanges.

4. Welded Connections

Welded end connections offer the highest level of sealing integrity and are common in mission-critical flight hardware.

- Butt Weld: Straight tube ends joined via orbital or manual fusion welding.

Best for: Propulsion lines, pressure vessels, and any system where leaks are unacceptable.

Engineering Insight:

Welded ends eliminate potential leak paths but require certified weld procedures and skilled labor. Ensure compatibility with welding codes and system accessibility before committing.

Key Considerations When Selecting a Connection Type

When specifying end connections, engineers should evaluate the following:

- System Pressure/Vacuum Requirements: Match the pressure rating of the fitting to the operating conditions.

- Material Compatibility: Ensure chemical and thermal compatibility between disk, fitting, and mating system.

- Assembly Environment: Consider whether the connection will be field-assembled, re-entered, or welded once.

- Weight and Volume Constraints: In mass-sensitive applications, compact connections like flare or compression styles may offer advantages.

ZOOK Aerospace Technologies: Custom-Engineered Connections for Aerospace Systems

At ZOOK Aerospace Technologies, we recognize that the right rupture disk is only as good as the system it’s integrated into. That’s why we offer rupture disks pre-configured with the full range of aerospace-ready end connections (e.g. threaded, flanged, welded, or custom hybrid assemblies).

Our engineering team collaborates directly with customers to ensure material compatibility, vibration resilience, and qualification testing across configurations. From high-vacuum environments to high-pressure propulsion, we tailor rupture disk solutions to meet your exact specifications.

Ready to Specify?

If you’re evaluating a rupture disk for a new or existing aerospace system, ZOOK Aerospace is ready to assist. Our team can help with:

- End connection selection

- System compatibility validation

- Custom designs for vacuum or pressure extremes